Plasma cutting collision repair revolutionizes automotive industry standards by offering precise, efficient, and heat-impact-minimizing metal cutting solutions. This innovative technology enables technicians to perform intricate repairs, straighten panels, and create custom shapes, leading to faster turnaround times and higher-quality outcomes for various vehicle components. Safety should be paramount when engaging in plasma cutting collision repair, with emphasis on well-ventilated workspaces, proper PPE, regular equipment maintenance, secure workbenches, clean organization, and current training.

In the realm of collision repair, technology plays a pivotal role in precision and efficiency. Plasma cutting has emerged as a game-changer, offering unparalleled accuracy and versatility. This article delves into the intricacies of plasma cutting technology for collision repair, exploring its advantages, applications, and best practices. Understanding these aspects ensures effective, safe, and high-quality repairs, making it an indispensable tool in modern automotive workshops. Discover how plasma cutting collision repair revolutionizes the industry, enhancing precision and productivity.

- Understanding Plasma Cutting Technology for Collision Repair

- Advantages and Applications in Collision Repair Process

- Best Practices and Safety Measures for Effective Plasma Cutting Collision Repair

Understanding Plasma Cutting Technology for Collision Repair

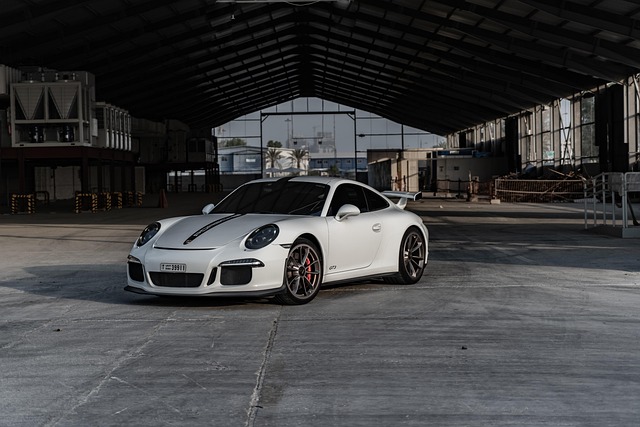

Plasma cutting technology has revolutionized collision repair and dent removal processes in car body shops. This innovative method involves using a plasma arc to cut through materials with precision, making it an ideal solution for complex bumper repairs and precise metal shaping. Unlike traditional cutting techniques, plasma cutting offers exceptional accuracy and speed, ensuring minimal heat impact on the surrounding material.

In the realm of collision repair, plasma cutting enables technicians to perform intricate repairs with ease, including straightening panels, cutting out damaged sections, and creating custom shapes for exact fits. Its versatility is particularly beneficial for repairing various vehicle components, from car bodies to fenders and grilles, ensuring a seamless restoration. This technology’s efficiency and precision contribute to faster turnaround times and higher-quality outcomes in the car body shop.

Advantages and Applications in Collision Repair Process

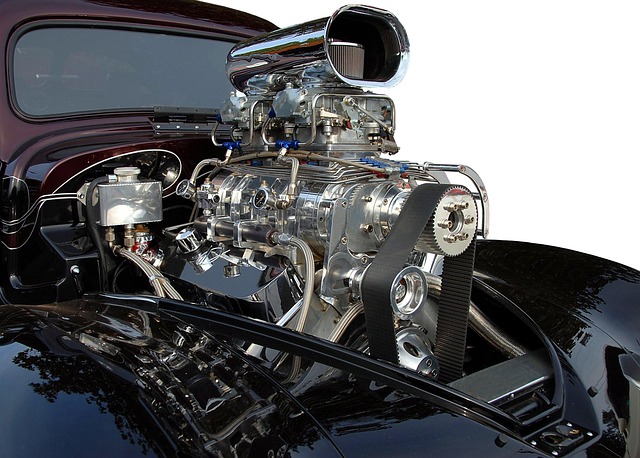

Plasma cutting collision repair has revolutionized the automotive industry, offering numerous advantages that streamline the collision repair process. This advanced technique is a game-changer for body shop services, providing precise and efficient metal cutting. Unlike traditional methods, plasma cutting delivers a clean, consistent cut with minimal heat input, preserving the integrity of surrounding materials. As a result, it’s a preferred method for car body repair, ensuring structural integrity and high-quality finishes.

The versatility of plasma cutting makes it suitable for various applications in collision repair. From cutting and notching metal panels to creating intricate patterns for vehicle paint repairs, this technology enhances precision and speed. Moreover, it facilitates complex geometric cuts, enabling technicians to handle challenging body panel replacements and modifications efficiently. With its ability to deliver precise results, plasma cutting has become an indispensable tool for achieving exceptional car body repair and vehicle paint repair outcomes.

Best Practices and Safety Measures for Effective Plasma Cutting Collision Repair

When engaging in plasma cutting collision repair, adhering to best practices and safety measures is paramount. Start by ensuring your workspace is well-ventilated to mitigate the risk of inhaling toxic fumes from cutting materials. Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a respirator designed for metalworking to safeguard against flying debris and harmful particles.

Regularly inspect and maintain your plasma cutter to guarantee optimal performance and precision. Utilize cutting tables or stable workbenches to secure the vehicle during repair, minimizing the risk of accidents. Maintain a clean and organized workspace to enhance efficiency and prevent damage to surrounding areas. Additionally, stay up-to-date with training and safety guidelines specific to plasma cutting techniques for auto body work and restoration, ensuring you deliver top-quality vehicle repair services.

Plasma cutting collision repair has emerged as a game-changer in the automotive industry, offering precise and efficient solutions. By understanding its technology, leveraging its advantages, and adhering to best practices, collision repair professionals can ensure high-quality outcomes while enhancing workshop productivity. Plasma cutting’s versatility and accuracy make it an indispensable tool for modern collision repair, allowing for faster turnaround times and reduced costs without compromising on quality.