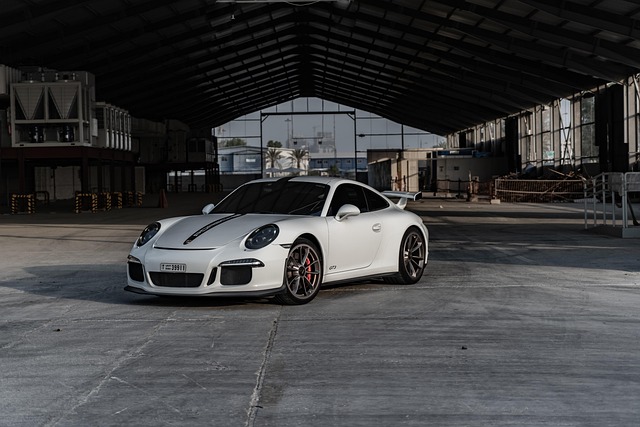

Plasma cutting technology has revolutionized collision repair services by offering an accurate, efficient, and safe method for dent removal and car repairs. This process uses a plasma arc to cut through metal with precision, handling various materials and thicknesses while minimizing damage. In luxury vehicle fabrication, professionals use advanced tools and safety measures, including eye and respiratory protection, to ensure accurate repairs. Plasma cutting also streamlines hail damage repair, reducing downtime. Combining advanced technology and skilled craftsmanship, plasma cutting collision repair delivers precise, efficient, and high-quality results, enhancing overall auto painting quality while meeting industry standards for long-lasting repairs.

Plasma cutting has emerged as a game-changer in the collision repair industry, offering precision and efficiency. This advanced technology allows for precise metal manipulation, making it ideal for complex auto body repairs. In this article, we’ll explore the key elements of plasma cutting collision repair. From understanding plasma cutting technology to mastering essential safety measures and efficient techniques, you’ll gain valuable insights into achieving precise results.

- Understanding Plasma Cutting Technology for Repairs

- Essential Tools and Safety Measures for Collision Repair

- Efficient Techniques to Achieve Precise Results

Understanding Plasma Cutting Technology for Repairs

Plasma cutting technology has revolutionized collision repair services, offering a precise and efficient method for dent removal and car collision repair. This innovative process involves using a plasma arc to cut through various materials, including metal panels and frames, with exceptional accuracy. By generating a high-velocity jet of ionized gas, plasma cutters can precisely shape, trim, or cut components, ensuring minimal heat impact on surrounding areas.

This technology is particularly beneficial in car collision repair due to its ability to mimic traditional cutting methods while reducing the risk of damage and deformity. Plasma cutters are highly versatile, capable of handling a wide range of materials and thicknesses, making them suitable for complex collision repair jobs. They also offer improved safety compared to conventional tools, as they eliminate many of the risks associated with fire and sparks.

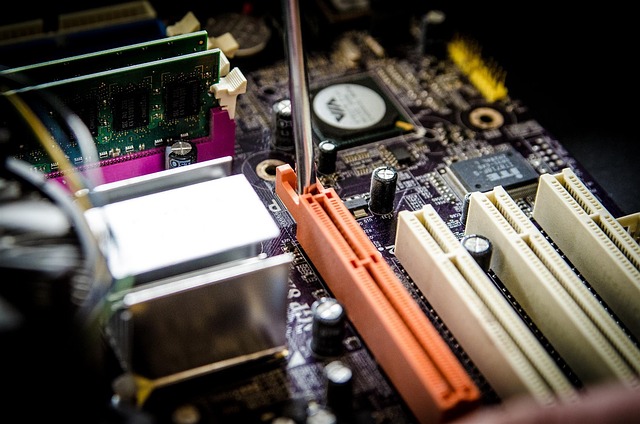

Essential Tools and Safety Measures for Collision Repair

In the realm of plasma cutting collision repair, professionals rely on a suite of essential tools and safety measures to ensure precise and effective repairs. At the heart of modern auto body repair, plasma cutters offer an advanced and versatile solution for various metal fabrication tasks, from straightening panels to removing damaged sections. These tools are particularly invaluable in luxury vehicle repair, where meticulous detail and precision are paramount.

Safety is paramount when engaging in plasma cutting collision repair. Proper protective gear, including eye and respiratory protection, is non-negotiable. Additionally, well-maintained and compliant ventilation systems are crucial for managing metal combustion byproducts, ensuring a safe work environment. For hail damage repair, where multiple panels may require attention, having the right tools and safety protocols in place can significantly streamline the process, minimizing downtime and maximizing vehicle restoration.

Efficient Techniques to Achieve Precise Results

In the realm of plasma cutting collision repair, efficiency and precision go hand in hand. Advanced techniques, such as utilizing high-definition plasma cutting machines, enable auto body shops to achieve intricate and accurate cuts with minimal waste. These machines are designed to cut through various materials, from steel to aluminum, with exceptional accuracy, making them ideal for complex collision repairs.

Moreover, combining plasma cutting with expert technique ensures a seamless blend during the car paint repair process. Fleet repair services often rely on these methods to restore vehicles to their pre-collision condition, focusing on both structural integrity and aesthetic appeal. Efficient plasma cutting not only saves time but also enhances the overall quality of auto painting, resulting in long-lasting repairs that meet the highest industry standards.

Plasma cutting collision repair combines advanced technology with precise techniques to deliver high-quality, efficient repairs. By understanding plasma cutting technology and implementing essential safety measures, along with mastering efficient techniques, professionals can ensure accurate and indelible results. These key elements not only revolutionize collision repair but also foster a vibrant, bustling industry that meets modern demands.