Plasma cutting collision repair leverages precise plasma arcs to cut and shape metal, offering speed, versatility, and minimal heat input for intricate auto body repairs. Despite higher costs, it's favored by professionals for superior results in painting and specialized treatments, catering to modern shops and classic vehicle enthusiasts. This guide outlines five steps using plasma cutters and CAD software for clean cuts, contouring, and seamless blending with original structures.

Plasma cutting has emerged as a game-changer in the automotive industry, transforming collision repair processes. This advanced technology offers precise, efficient metal fabrication, making it ideal for complex auto body work. This article delves into the intricacies of plasma cutting collision repair, exploring its benefits and limitations. We provide a comprehensive step-by-step guide to help professionals master this technique, ensuring optimal results in their repair practices.

- Understanding Plasma Cutting Technology for Collision Repair

- Advantages and Limitations of Plasma Cutting in Auto Body Work

- Step-by-Step Guide to Effective Plasma Cutting Collision Repair

Understanding Plasma Cutting Technology for Collision Repair

Plasma cutting technology has emerged as a game-changer in the realm of collision repair, offering precise and efficient results. This innovative process involves using a plasma arc to cut through various materials, including metal, with exceptional accuracy. Unlike traditional cutting methods, plasma cutting collision repair provides clean, seamless cuts, minimizing material waste. The technology is particularly beneficial for complex auto body services, where precision and speed are paramount.

Understanding how plasma cutting works involves grasping the science behind the plasma arc. By ionizing a gas, typically air or a mixture of gases, an electric current creates a superheated plasma that travels at high speeds to melt and cut through the target material. This method is not only suitable for straight cuts but can also handle intricate patterns and curves, making it ideal for the detailed work required in body shop services. Its versatility and speed make plasma cutting a preferred choice for collision repair professionals, ensuring superior results in auto painting and other specialized auto body services.

Advantages and Limitations of Plasma Cutting in Auto Body Work

Plasma cutting has emerged as a powerful tool in the realm of auto body work, offering several advantages that make it a preferred choice for many automotive professionals. One of its key strengths is precision; this technique enables highly accurate cuts, allowing for intricate and detailed repairs, especially in complex collision scenarios. It is particularly effective for shaping metal panels, retaining their structural integrity while facilitating precise adjustments. Additionally, plasma cutting produces minimal heat input, reducing the risk of warping or damaging surrounding materials, which is crucial during collision repair where preserving the original car bodywork is essential.

Despite its benefits, plasma cutting also has limitations. The process requires a higher initial investment in specialized equipment compared to traditional cutting methods. Moreover, it may not be suitable for all types of metals or thicknesses; thinner sheets might require additional support during cutting to prevent distortion. For classic car restoration projects where authenticity is paramount, the risk of heat-related damage to vintage finishes and components must be carefully managed. Nonetheless, with proper training and expertise, plasma cutting collision repair provides an efficient and reliable solution for auto body shops aiming to deliver top-quality repairs, catering to both modern and classic vehicles, including those sought after by enthusiasts near every auto repair near me.

Step-by-Step Guide to Effective Plasma Cutting Collision Repair

Plasma cutting collision repair is a specialized process that involves using plasma arcs to cut and shape metal, which is particularly useful in automotive collision repair and vehicle body repair scenarios. Here’s a step-by-step guide for effective plasma cutting collision repair:

1. Preparation: Begin by thoroughly inspecting the damaged area of the vehicle. Remove any debris or loose parts. Ensure proper ventilation as plasma cutting can generate intense heat and harmful fumes. Set up your plasma cutter, ensuring it’s calibrated accurately for optimal performance.

2. Design and Layout: Create a precise layout and design of the required cut using computer-aided design (CAD) software if possible. This ensures accuracy and minimizes waste. Mark the cutting lines on the vehicle body clearly to guide your plasma arc.

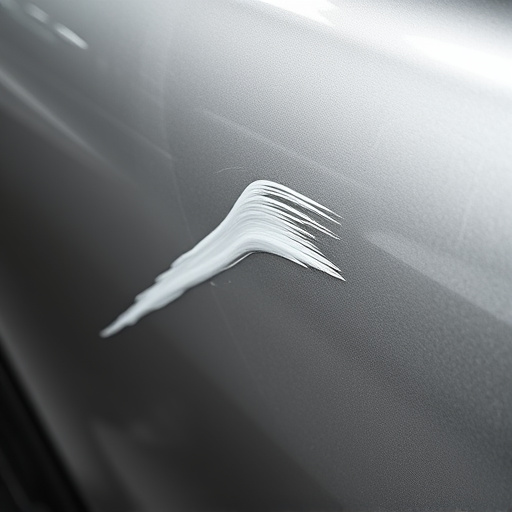

3. Cutting Process: Position the plasma cutter along the marked line, activating the arc gently at first to test its intensity. Gradually increase the power while maintaining a steady speed. The plasma arc should cut through the metal cleanly and efficiently. Be cautious of over-cutting or overheating, which can lead to distortion or damage.

4. Contouring and Shaping: For more intricate repairs, use the plasma cutter to contour and shape the metal precisely. This step is crucial in dent repair, as it helps to return the vehicle body to its original form. Be meticulous to avoid unnecessary damage to surrounding areas.

5. Finishing Touches: Once the cutting and shaping are complete, clean the area thoroughly to remove any metal shavings or residue. Inspect your work for accuracy and smoothness. If necessary, perform additional finishing techniques such as grinding or welding to blend the repair seamlessly with the rest of the vehicle body.

Plasma cutting collision repair is a game-changer in the auto body industry, offering precise and efficient metal fabrication. By understanding its technology, leveraging its advantages, and following a structured step-by-step guide, technicians can achieve high-quality results while enhancing their workflow. As this method continues to evolve, adopting plasma cutting for collision repair is an intelligent choice for professionals looking to stay ahead in the market.