Plasma cutting collision repair is a game-changer in the auto industry, offering unparalleled precision, speed, and efficiency. This advanced technology utilizes a high-velocity jet of ionized gas to melt and vaporize metal with minimal heat impact, making it ideal for diverse metal types like steel, aluminum, and stainless steel. By streamlining preparation time, reducing costs, preserving vehicle aesthetics, and enhancing productivity, plasma cutting sets a new standard in collision repair and auto body restoration, suitable for everything from minor dents to major collision damage.

Plasma cutting collision repair is transforming the automotive industry by offering a highly efficient and precise solution for vehicle restoration. This innovative technology, which uses a high-velocity jet of ionized gas to cut metal, presents numerous advantages over traditional methods. From faster turnaround times to reduced material waste, plasma cutting enhances repair efficiency, ensuring superior outcomes. This article explores how this advanced technique revolutionizes collision repair processes, addressing key benefits and optimal techniques for maximizing its potential.

- Understanding Plasma Cutting Technology for Collision Repair

- Advantages of Using Plasma Cutting in Collision Repair Processes

- Optimizing Repair Efficiency with Plasma Cutting Collision Repair Techniques

Understanding Plasma Cutting Technology for Collision Repair

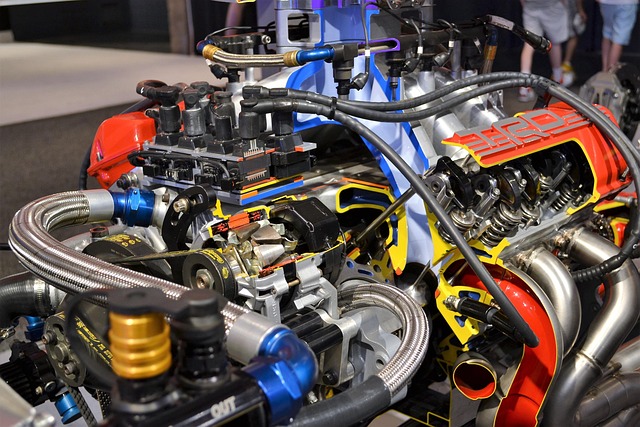

Plasma cutting technology has emerged as a game-changer in the realm of collision repair, offering unprecedented precision and efficiency. This innovative process utilizes a high-velocity jet of ionized gas to cut through various materials, including metal bodies of vehicles involved in collisions. By generating intense heat, plasma cutting swiftly melts and vaporizes the material, leaving behind a clean, precise cut.

For collision centers dealing with car restoration, this technology is a boon. It enables faster turnaround times as it minimizes the amount of manual labor required to achieve complex cuts. Unlike traditional cutting methods, plasma cutting collision repair produces minimal heat-affected zones, ensuring the structural integrity and aesthetic appeal of the restored vehicle. This precision translates to better overall quality in vehicle collision repair and car restoration processes.

Advantages of Using Plasma Cutting in Collision Repair Processes

Plasma cutting collision repair offers numerous advantages over traditional cutting methods in vehicle repair processes. One key benefit is its precision and speed. Plasma cutters use a high-velocity jet of ionized gas to cut through metal, allowing for clean, accurate cuts with minimal heat impact on surrounding areas. This precision ensures that even complex auto detailing work can be executed flawlessly, preserving the original look and feel of the vehicle.

Moreover, plasma cutting is particularly effective in handling various materials commonly found in collision repair, such as steel, aluminum, and stainless steel. Its ability to cut through different metal types efficiently reduces preparation time, making it a cost-effective solution for auto glass repair and overall vehicle repair. By streamlining these processes, plasma cutting collision repair enhances productivity while maintaining high-quality standards in auto detailing work.

Optimizing Repair Efficiency with Plasma Cutting Collision Repair Techniques

Plasma cutting collision repair techniques are revolutionizing the way we approach auto body restoration and frame straightening. By utilizing precision plasma cutting technology, skilled technicians can now optimize repair efficiency, achieving flawless results faster than ever before. This advanced method allows for accurate and clean cuts, making it ideal for complex car dent repairs and intricate body panel replacements.

Unlike traditional methods that might require more time-consuming hand-cutting or less precise machinery, plasma cutting offers a game-changer in the automotive repair industry. It enhances overall efficiency by reducing the need for manual labor, minimizing material waste, and ensuring consistent quality throughout the repair process. With its ability to handle a variety of metal types and thicknesses, this versatile technique is perfect for both minor car dents and major collision damage, ultimately streamlining the entire car body restoration process.

Plasma cutting collision repair offers a game-changing approach to automotive restoration, revolutionizing traditional repair methods. By leveraging advanced plasma cutting technology, repair technicians can achieve unprecedented efficiency and precision. The advantages, such as faster material removal, reduced heat input, and minimal distortion, contribute to a streamlined repair process. Through optimized techniques, including strategic cut patterns and automated systems, collision repair shops can significantly enhance productivity, ensuring faster turnaround times and superior results for customers seeking top-quality repairs.