Plasma cutting collision repair revolutionizes automotive body work with its precise, non-invasive method using a plasma arc to cut metal cleanly and swiftly. Ideal for classic car restoration, it maintains aesthetic integrity by minimizing damage to underlying materials, reducing vehicle downtime, and offering unparalleled precision and quality in repairs.

Plasma cutting collision repair is transforming the automotive industry. This innovative technique leverages advanced plasma cutting technology to offer unparalleled precision and efficiency in vehicle restoration. By understanding how plasma cutting works, you gain insights into its significant advantages in the collision repair process. Discover how this method enhances precision, ensures high-quality results, and revolutionizes traditional repair techniques.

- Understanding Plasma Cutting Technology

- Advantages in Collision Repair Process

- Enhancing Precision and Quality Results

Understanding Plasma Cutting Technology

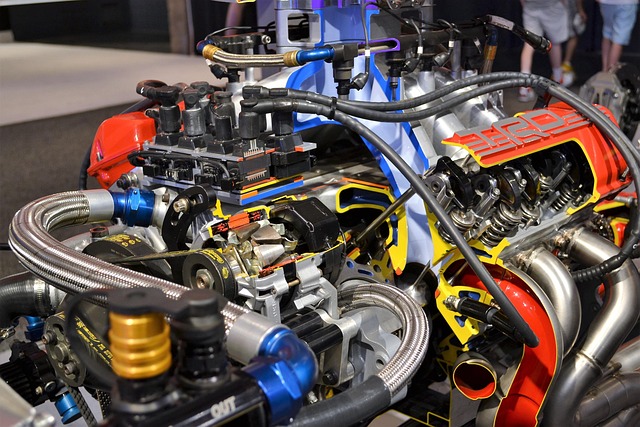

Plasma cutting technology has revolutionized collision repair services within automotive body shops and car repair shops alike. This advanced process involves using a plasma arc to cut through materials with exceptional precision, making it an invaluable tool for intricate metal fabrication. Unlike traditional cutting methods, plasma cutting offers a highly controlled and consistent approach, ensuring accurate results every time.

The technology leverages a high-voltage electrical discharge to create a plasma torch that generates extreme heat, melting and ionizing the material being cut. This precise and focused energy allows for clean, swift cuts, even in hard-to-reach areas. In collision repair, where precision is key, plasma cutting ensures that panels are removed or reshaped without damaging surrounding surfaces, leading to higher-quality repairs and improved overall aesthetics in the final restoration of vehicles at these automotive body shops and car repair shops.

Advantages in Collision Repair Process

The integration of plasma cutting technology into collision repair processes offers several significant advantages. One of the key benefits is its precision; plasma cutters provide highly accurate cuts, enabling detailed and delicate work that was previously challenging to achieve. This precision is particularly valuable in classic car restoration projects, where maintaining the vehicle’s original aesthetic integrity is paramount.

Moreover, plasma cutting improves efficiency in hail damage repair or vehicle paint repair scenarios. The non-invasive nature of the process minimizes the risk of damaging underlying materials during repairs, ensuring a more straightforward and faster restoration. This advantage translates into reduced downtime for vehicles, making it an efficient solution for both minor dents and extensive collision damage.

Enhancing Precision and Quality Results

One of the most significant advantages of plasma cutting collision repair is its ability to enhance precision and quality results in automotive collision repair. Unlike traditional cutting methods, plasma cutting utilizes a highly focused beam of ionized gas that can cut through metal with remarkable accuracy, allowing for intricate and detailed work. This level of precision ensures that even complex geometric shapes and tight radii can be achieved, resulting in superior vehicle restoration outcomes.

By employing plasma cutting technology, automotive collision repair specialists can achieve consistently accurate cuts every time, minimizing the risk of human error. This not only speeds up the overall restoration process but also guarantees a higher level of detail and finish. Consequently, plasma cutting collision repair sets a new standard for automotive restoration, delivering vehicles that are not just structurally sound but also aesthetically stunning.

Plasma cutting collision repair is transforming the automotive industry by offering unparalleled precision and quality. By leveraging advanced plasma cutting technology, collision repair technicians can achieve accurate, clean cuts, streamlining the repair process and resulting in superior final outcomes. This innovative approach ensures that vehicles not only look good but also perform optimally after repairs, setting a new standard for excellence in collision repair services.