Plasma cutting collision repair has emerged as a game-changer in the auto body industry, offering precise, efficient, and versatile solutions for intricate dent removal and precision repairs. This technology utilizes a plasma arc to cut metal with minimal heat input, resulting in clean, accurate cuts that reduce waste and turnaround times compared to traditional methods. By preserving the vehicle's aesthetic quality and enhancing repair quality, plasma cutting collision repair stands out for its superior outcomes and customer satisfaction. Best practices, including meticulous planning, advanced tool inspections, and systematic assembly, ensure pristine restoration, making plasma cutting a revolutionary innovation in auto body services.

Plasma cutting collision repair is transforming the automotive industry, offering enhanced precision and efficiency. This article delves into the world of plasma cutting technology, exploring how it fundamentally improves repair quality. We’ll dissect its advantages, from precise metal manipulation to reduced heat impact on surrounding materials. Furthermore, we provide best practices and tips for professionals looking to master this game-changing technique in collision repair.

- Understanding Plasma Cutting Technology for Collision Repair

- Advantages of Plasma Cutting in Enhancing Repair Quality

- Best Practices and Tips for Effective Plasma Cutting Collision Repair

Understanding Plasma Cutting Technology for Collision Repair

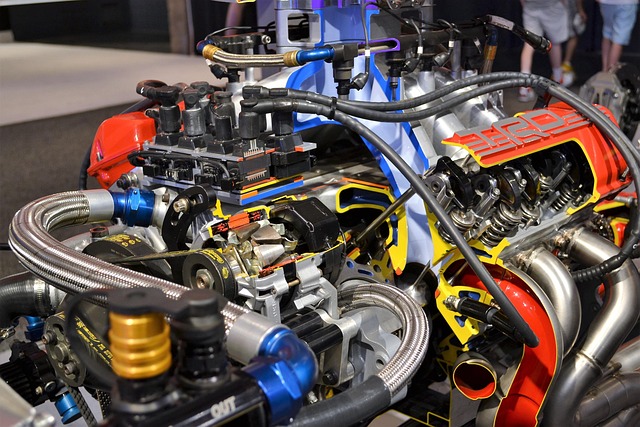

Plasma cutting technology has emerged as a game-changer in the realm of collision repair, offering precise and efficient solutions for auto body shops. This innovative process involves using a plasma arc to cut through metal, which results in clean, accurate cuts with minimal heat input. For collision repair professionals, this means achieving superior quality car restoration while minimizing the risk of warping or damaging the surrounding material.

In a bustling body shop environment where time and precision are paramount, plasma cutting collision repair stands out as a specialized service. Unlike traditional cutting methods, plasma cutting reduces the need for heavy machinery and excessive force, translating to faster turnaround times and less waste. Moreover, its versatility allows for intricate cuts and custom designs, making it ideal for both minor repairs and complex restoration projects within an auto body shop’s scope of services.

Advantages of Plasma Cutting in Enhancing Repair Quality

Plasma cutting collision repair has revolutionized car body repair, offering significant advantages over traditional methods. This advanced technique is particularly beneficial for intricate dent removal and precision vehicle repair. By utilizing a plasma arc to cut through metal, repair technicians can achieve remarkable accuracy and efficiency. The highly focused heat source enables the removal of damaged panels with minimal distortion, preserving the overall aesthetic quality of the vehicle.

Moreover, plasma cutting provides a cleaner and more consistent cut, reducing the need for extensive grinding or sanding during the dent removal process. This precision leads to faster turnaround times and higher-quality repairs, ensuring that vehicles return to their pre-accident condition. In the realm of collision repair, where detail matters, plasma cutting stands out as a game-changer, enhancing overall repair quality and customer satisfaction in vehicle repair.

Best Practices and Tips for Effective Plasma Cutting Collision Repair

When it comes to plasma cutting collision repair, adhering to best practices ensures optimal results for car collision repair and auto body services. Pre-cutting planning is key; thoroughly assess the damage, create precise templates, and account for material thickness variations. Using advanced plasma cutters with adjustable settings allows for clean, controlled cuts, minimizing heat-affected zones and ensuring structural integrity during car body restoration.

During the repair process, maintaining a clean workspace and utilizing appropriate personal protective equipment (PPE) is essential. Regularly inspecting cutting tools for wear ensures consistent performance. Additionally, employing a systematic approach to welding and bolting reassembles components in a logical sequence, facilitating seamless integration. Remember that quality checks at each stage prevent errors and ensure the final restoration meets high standards in both aesthetics and structural soundness, making plasma cutting collision repair a game-changer in auto body services.

Plasma cutting collision repair has emerged as a game-changer in the automotive industry, offering enhanced precision and efficiency. By understanding this technology and implementing best practices, repair shops can consistently deliver high-quality results. The advantages of plasma cutting are clear: improved accuracy, faster cut times, and reduced material waste. With these benefits, plasma cutting collision repair sets a new standard for excellence, ensuring that vehicles return to the road with indelible repairs that withstand the test of time.