Plasma cutting collision repair redefines automotive bodywork with unparalleled accuracy and efficiency. This technology minimizes heat input while precisely cutting various materials, preserving vehicle integrity for hail damage or fender bender repairs. Its versatility allows for clean cuts, rust prevention, intricate designs, and exact specifications, making it a go-to method for professional technicians in both accident restoration and custom projects.

In the realm of collision repair, achieving precision is paramount. Plasma cutting technology emerges as a game-changer, offering unparalleled accuracy and efficiency. This innovative approach transcends traditional cutting methods, enabling technicians to navigate complex landscapes with finesse. By understanding the intricacies of plasma cutting, repair shops can harness its advantages, from enhanced material removal to precise bead profiles, ensuring top-notch craftsmanship and customer satisfaction in every collision repair project.

- Understanding Plasma Cutting Technology for Repairs

- Advantages of Plasma Cutting in Collision Repair

- Achieving Precision and Accuracy Through Plasma Cutting

Understanding Plasma Cutting Technology for Repairs

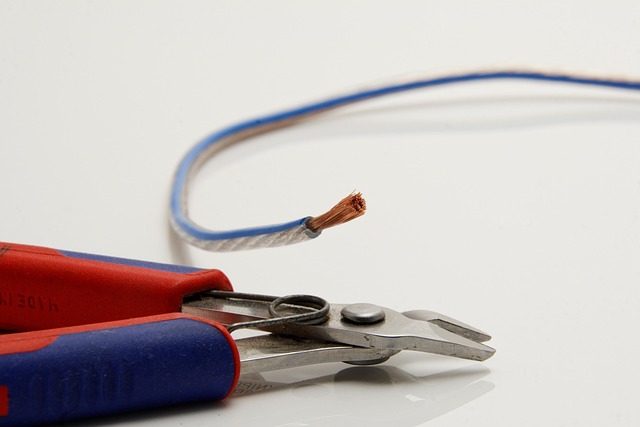

Plasma cutting technology has revolutionized the landscape of collision repair, offering unprecedented accuracy and efficiency. This advanced process involves using a plasma arc to cut through various materials, including metal sheets and components commonly found in car body repair. The key advantage lies in its precision, enabling skilled technicians to make clean, controlled cuts with minimal heat input, which is crucial for preserving the structural integrity of damaged vehicles.

For hail damage repair or other types of car repairs, plasma cutting collision repair stands out as a game-changer. Unlike traditional cutting methods, plasma cutting minimizes distortion and ensures exact specifications, which is essential in aligning panels and parts accurately. This precision not only speeds up the repair process but also enhances the overall quality of car repair services, resulting in vehicles that look and perform like new.

Advantages of Plasma Cutting in Collision Repair

Plasma cutting has emerged as a game-changer in the realm of collision repair, offering numerous advantages over traditional methods. Its precision and versatility make it an invaluable tool for automotive body shops dealing with various damage scenarios, from car scratch repairs to more intricate paintless dent repair tasks.

This modern technique ensures accuracy and efficiency in cutting and shaping metal panels, which is crucial for aligning vehicle bodies post-accident or during routine maintenance. Plasma cutting collision repair allows for clean, smooth cuts, minimizing the risk of rust and ensuring the structural integrity of the vehicle. Moreover, it facilitates complex design patterns and intricate details in custom automotive restoration projects, showcasing the versatility that makes this method a favorite among professional technicians.

Achieving Precision and Accuracy Through Plasma Cutting

Plasma cutting collision repair stands out as a game-changer in the automotive industry, particularly when it comes to car dent removal and fender bender repairs. This advanced technique utilizes concentrated plasma to cut through metal with unprecedented precision, ensuring minimal heat input and material distortion. Unlike traditional cutting methods, which can leave unsightly burn marks or warping, plasma cutting delivers a clean, precise cut that preserves the integrity of the vehicle’s bodywork services.

The accuracy afforded by plasma cutting is invaluable when addressing complex car bodywork repairs. Its ability to cut through various metal thicknesses and shapes with ease makes it an indispensable tool in fixing fender benders and other types of damage. By maintaining strict control over the cutting process, technicians can achieve seamless panel replacements, precise alignment, and a restoration that mirrors the vehicle’s original condition, effectively eliminating visible evidence of the collision.

Plasma cutting collision repair stands as a game-changer in the automotive industry, offering unprecedented precision and efficiency. By leveraging advanced plasma cutting technology, professionals can achieve intricate details and exact measurements, ensuring top-quality repairs that match the original vehicle’s specifications. This article has highlighted the key benefits, from understanding the technology to its ability to deliver accuracy, making it an indispensable tool for accurate and reliable collision repair.