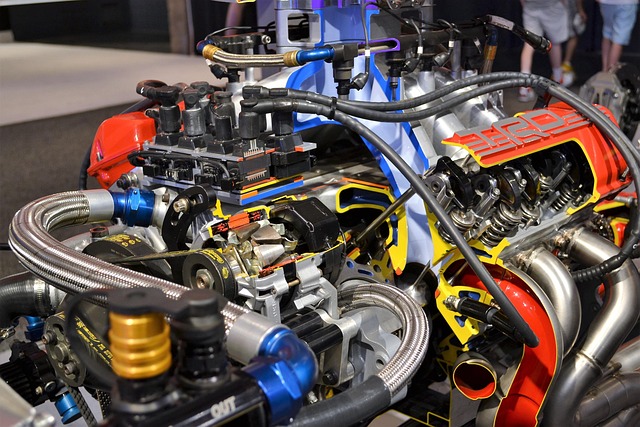

Plasma cutting collision repair is a game-changer in auto repair, offering unparalleled precision and efficiency. Using ionized gas, it cleanly cuts materials with minimal removal, preserving original parts and enhancing aesthetics. Ideal for luxury vehicle repair, it saves time, money, and resources while ensuring high-quality finishes and reducing labor costs. This advanced technique requires skill to cut metal accurately, achieving flawless integrations in bumper repairs and showcasing exceptional craftsmanship.

Plasma cutting collision repair stands out as a game-changer in the automotive restoration industry. This innovative technique offers unparalleled precision, making it an ideal solution for complex and intricate repairs. By utilizing plasma technology, collision repair shops can achieve maximum efficiency and exceptional quality. The ability to cut through various materials with accuracy ensures that every detail is restored, resulting in a seamless and perfect restoration. Discover how plasma cutting is revolutionizing the art of collision repair and why it’s becoming the go-to method for accurate and efficient fixes.

- Unparalleled Precision: Plasma Cutting's Advantage

- Collision Repair: Maximizing Efficiency and Quality

- The Art of Restoration: Achieving Exact Results

Unparalleled Precision: Plasma Cutting's Advantage

Plasma cutting stands out as a game-changer in the realm of collision repair, offering unparalleled precision that sets it apart from traditional cutting methods. This advanced technique utilizes a high-velocity stream of ionized gas to cut through various materials with remarkable accuracy, making it an ideal solution for intricate auto repair services. Unlike other methods that might leave behind jagged edges or require extensive finishing work, plasma cutting ensures clean, precise cuts every time.

For luxury vehicle repair and car paint services where meticulousness is paramount, plasma cutting collision repair is particularly valuable. Its precision allows for minimal material removal, preserving the integrity of the original parts and reducing the need for extensive rework. This not only saves time and money but also guarantees a higher quality finish, making it a preferred choice among professionals in the automotive industry.

Collision Repair: Maximizing Efficiency and Quality

In the realm of collision repair, achieving both efficiency and quality is paramount to customer satisfaction and ensuring the safety of vehicles. Plasma cutting collision repair stands out as a game-changer in this industry. This advanced technique utilizes focused plasma arcs to cut through various materials with precision, allowing for intricate and accurate repairs. By employing plasma cutting, technicians can efficiently remove damaged components while preserving the integrity of surrounding areas, particularly crucial in the delicate process of auto glass repair or sophisticated luxury vehicle repair.

Maximizing efficiency isn’t just about saving time; it translates into reduced labor costs and faster turnaround times for customers. Moreover, the precision afforded by plasma cutting minimizes the risk of further damage during the collision repair process, ensuring that every dent repair is executed with meticulous care. This level of accuracy is vital in maintaining the original aesthetic appeal and structural soundness of vehicles, whether they are standard or luxury models.

The Art of Restoration: Achieving Exact Results

The art of restoration is a delicate dance, where every stroke and cut demands precision and skill. When it comes to plasma cutting collision repair, this artistic approach becomes even more critical. This advanced technique involves utilizing high-speed plasma arcs to cut and shape metal with remarkable accuracy. By employing plasma cutting, restoration specialists can achieve intricate designs and precise dimensions, ensuring that every piece of car damage repair is not just fixed but restored to its original glory.

In the world of vehicle restoration, especially when dealing with bumper repair, the goal is flawless integration. Plasma cutting enables technicians to remove damaged or dented areas while preserving the surrounding, intact surface. This level of control allows for meticulous adjustments during the bumper repair process, resulting in seamless transitions and a visually appealing finish. The art of restoration truly shines when these techniques are harnessed, transforming car damage into a testament to craftsmanship and technical prowess.

Plasma cutting collision repair stands out as a game-changer in the automotive restoration industry. Its unparalleled precision ensures that every detail is accounted for, allowing for maximum efficiency and quality during the repair process. By leveraging the advanced capabilities of plasma cutting, restorers can achieve exact results, restoring vehicles to their original state with minimal fuss. This technology is not just a tool; it’s a testament to the art of restoration, where accuracy meets artistry.